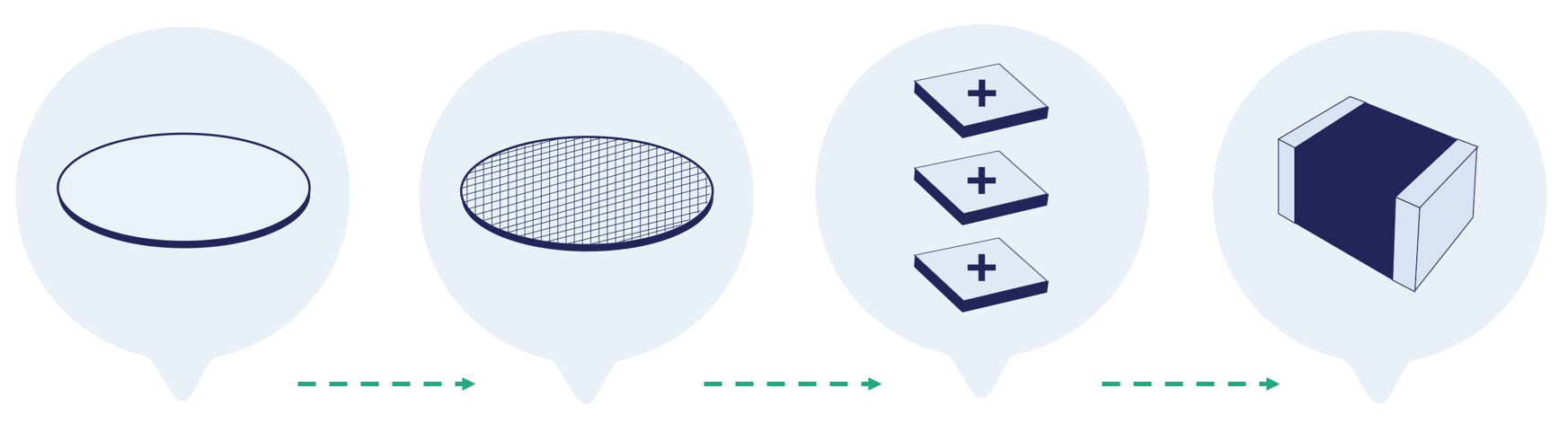

Advanced Porous Wafers

Our process starts with highly porous anodic aluminum oxide wafers. This porosity allows high energy density while using thin-film electrodes which enable high power.

Pattern and Process

We then use standard semi-conductor processes to pattern the wafer and produce an array of solid-state batteries. Imagine each little square is its own SSB!

Dice and Stack

After the batteries are deposited into the patterned wafer we cut it up into little pieces called dies. At this point each die is working solid-state battery. We then stack and wire them up to increase the total energy of the final cell.

Package

The final packaged cell has a lot of flexibility. By leveraging capacitor packaging we can tune the final voltage of the cell and the total amount of energy. No external pressure required for operation!